CAPABILITIES.

CONSTRUCTION

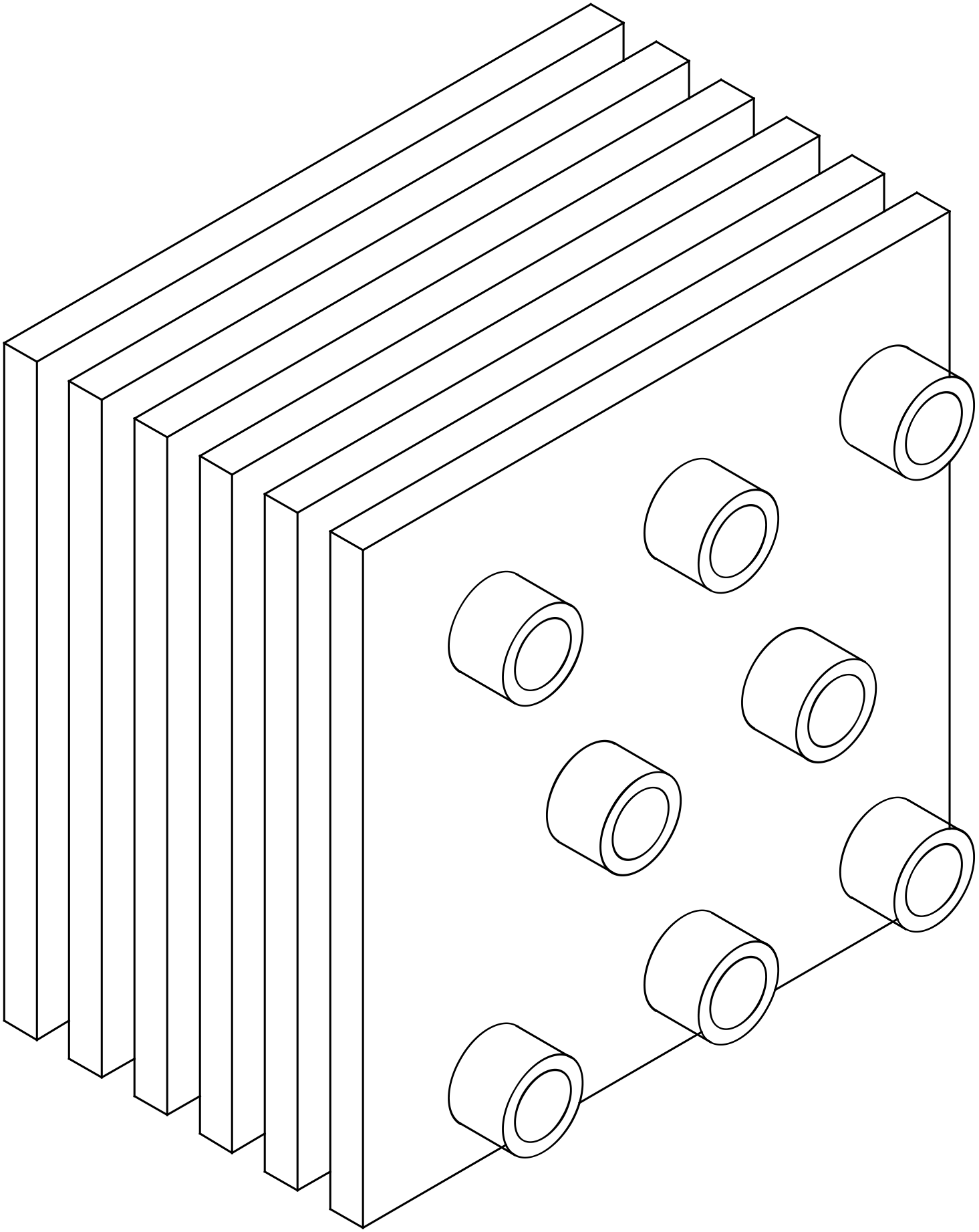

Tube Fin Exchanger with Flat Fins

HEADERS

Rectangular Manifold style headers & Pipe headers. Standard Materials: Carbon Steel, Stainless Steel

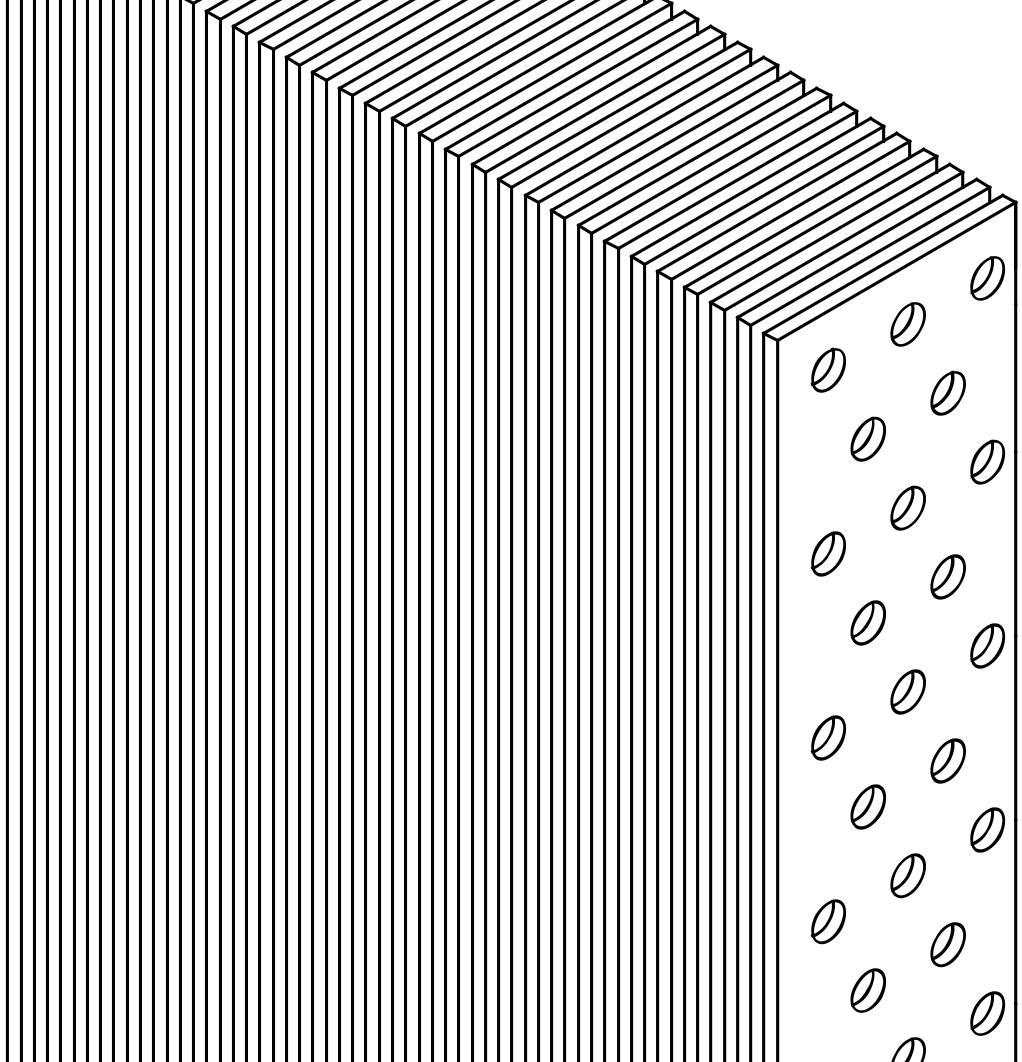

FINS

Flat continuous plate fins maximize heat transfer with low air side friction. Standard Material: Steel

TUBES

Small diameter, 0.028 to 0.065 wall thickness, ERW and seamless. Standard Materials: Carbon Steel, Stainless Steel

NICKEL-BRAZED TUBE TO MANIFOLD JOINTS

Tubes are joined to manifolds with a nickel alloy using a vacuum brazing furnace.

Unlike rolled tube-tubesheet joints, our specialty brazing process creates a permanent bond between the tube and manifold. The nickel alloy braze compound forms a joint stronger than both steel base metals.

As opposed to “yellow” brazing alloys, our nickel based braze compound is compatible with sour gas and other corrosive applications.

Our state of the art vacuum brazing furnace also allows us to stress relief anneal the rigid nickel brazed joint, as well as heat treat per ASME.

KEY FEATURES OF OUR DESIGN

Our advanced turbulator design used in our oil coolers and radiators is superior to conventional designs. It greatly increases efficiency while resisting fouling and plugging. It is offered in both carbon steel and stainless steel construction.

Requires minimal maintenance.

Brazed tube-header joints mean tubes never need to be re-rolled.

Access plugs are not required. This greatly reduces the the total number of joints and potential failure points and streamlines the manufacturing process.

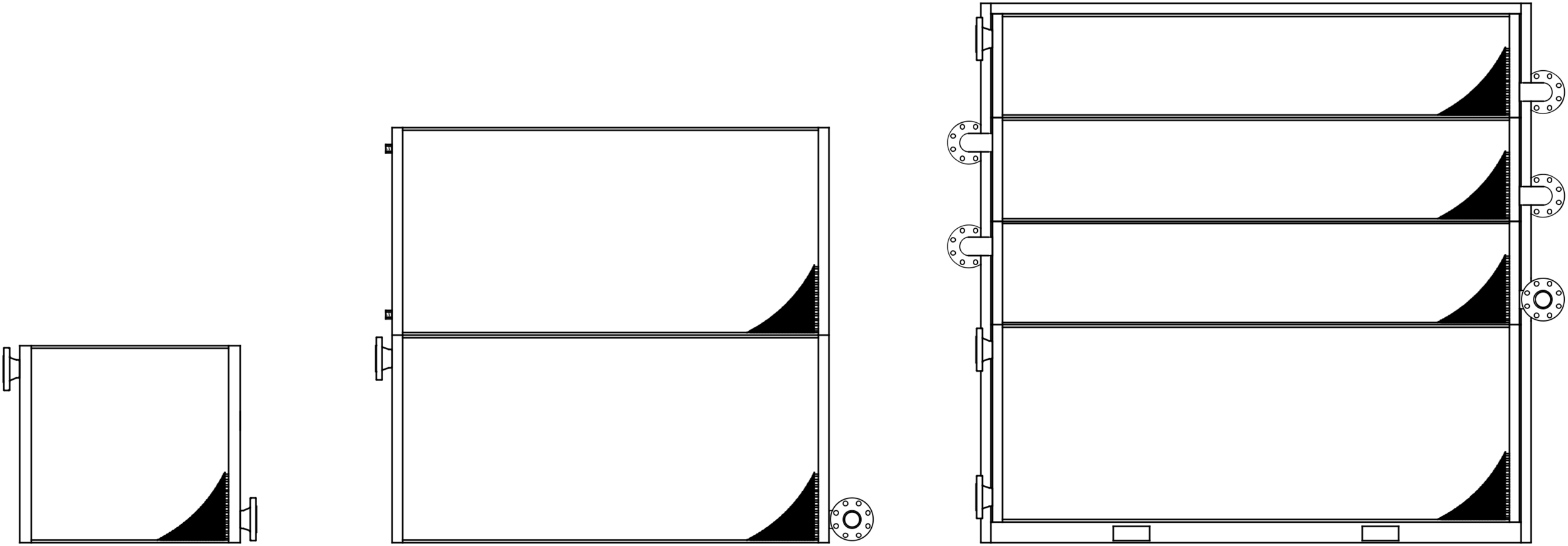

Removable cooler sections.

Quick and easy replacement/repair of damaged coolers.

Eliminates downtime for costly tube inspection, removal, cleaning and re-rolling.

Allows for easy access to fan and drive components from the front without the need to disassemble the entire back end of the cooler.

CERTIFICATIONS

- ASME Section VIII Div. 1 (U, UM, R)

- NATIONAL BOARD

- API 661

- CRN

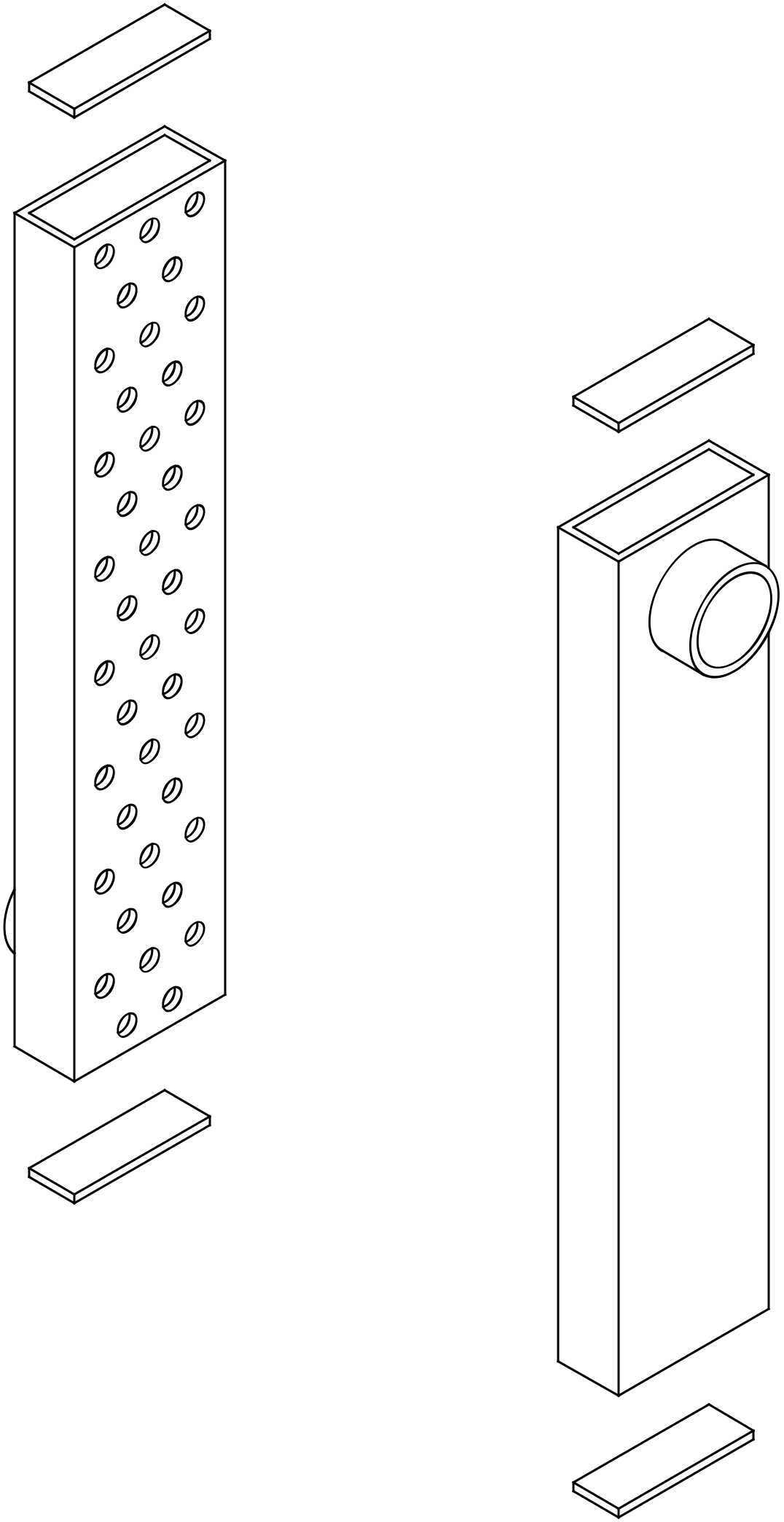

CORE CONFIGURATIONS

STAND CONFIGURATIONS

Vertical airflow, forced/induced draft, cores in parallel or series.

Vertical core, Horizontal airflow, forced draft, cores in parallel or series.

AXIAL FANS

Glass reinforced polyamide, polypropalene and aluminum blades.

9" to 96" diameter.

FAN DRIVE

- Electric motor, direct/belt drive, 1/4 HP to 60 HP, AC and DC

- Engine shaft, direct/belt drive

- Hydraulic motor

- Compressor flywheel

ACCESSORIES

- Thermal and pressure bypass valves

- Temperature switch

- Louvers, manual/actuated, intake/exhaust/recirculating

- Vibration sensors

- Hail guards

- Day tanks

- Coatings: E-coat, hot dipped galvanized, 2-part epoxy

PRESSURE CAPABILITIES

We currently are capable of manufacturing coolers rated up to 5000 PSIG.